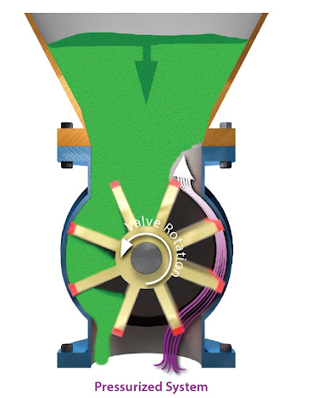

A rotary airlock valve is a type of rotary feeder used in pneumatic conveying systems to control the flow of bulk materials while maintaining a sealed environment. It consists of a cylindrical housing with a rotating rotor inside, which has vanes or blades that create pockets to trap and discharge materials.

Rotary airlock valves are commonly used in industries such as food processing, pharmaceuticals, chemicals, and plastics, where a continuous and controlled flow of materials is essential. They are typically installed in pneumatic conveying systems, dust collection systems, and other air handling applications.

For example, in a pneumatic conveying system used to transport powdered or granular materials, a rotary airlock valve serves as an airlock between the positive pressure of the conveying line and the lower pressure of the receiving vessel. It allows materials to be discharged from the conveying line into the receiving vessel while preventing backflow of air or loss of pressure.

The design of rotary airlock valves can vary based on factors such as material characteristics, flow rate requirements, and operating conditions. They may feature different rotor configurations, housing materials, and sealing options to suit specific application needs.

Overall, rotary airlock valves play a critical role in pneumatic conveying systems, ensuring efficient material transfer while maintaining system integrity and preventing air leakage or contamination.